Precision Injection Moulding Solutions for Manufacturing Success

Holloway Emerge specialises in offering cutting-edge injection moulding services. Our 14 state-of-the-art facilities and skilled team ensure precision and quality throughout the entire manufacturing process, delivering impeccable results for diverse industries.

Get in Touch with Us

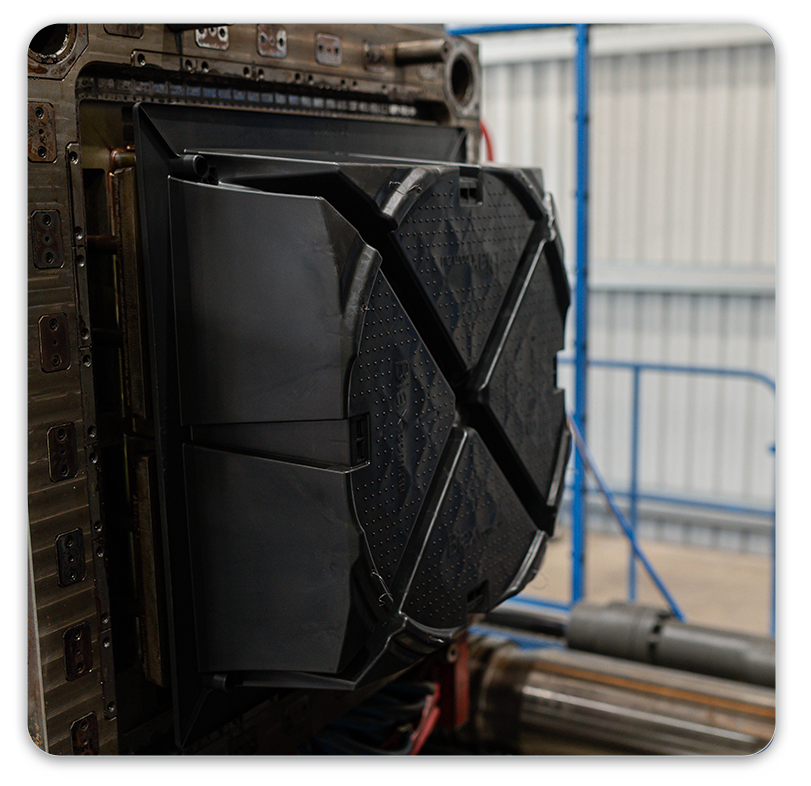

We specialise in plastic injection moulding, an advanced manufacturing process that effortlessly produces parts from both thermoplastic and thermosetting plastic materials. With our cutting-edge facility equipped with 14 state-of-the-art, energy-efficient moulding machines and robotics, we ensure unwavering consistency in quality and cycle time.

Trust us as your preferred moulding maker, where we leverage state-of-the-art 3D technology to achieve unparalleled precision and uniformity in each part. Our dedicated team of seasoned customer moulders possesses the expertise to tackle any project, no matter how intricate or demanding it may be.

Get In TouchWhat is Injection Moulding?

Injection moulding allows for the production of high volumes of parts in a short amount of time.

Material is fed into a plastic injection moulding machine where it is heated, mixed, and forced into the mould cavity where it cools and hardens to the configuration of the cavity. This allows for precision in each mould that is created.

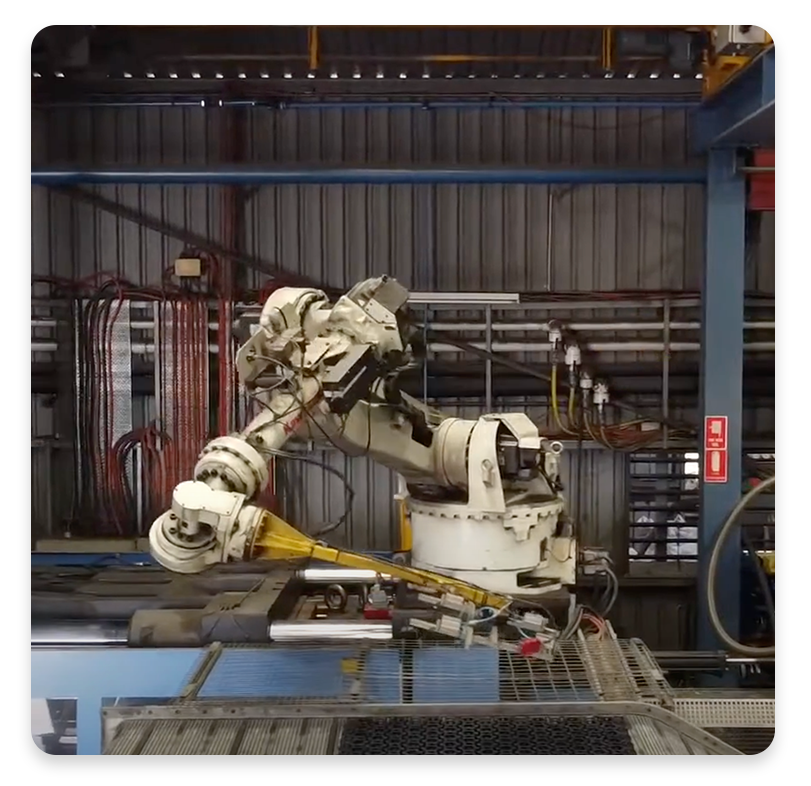

Automation

Our 14 machines utilise either 3 or 6-axis robots to extract parts from the machines. This allows our experienced operators to work on 2 or 3 machines at one time. Our robots also guarantee consistency of cycle time, ensuring we can give our customers the most competitive price.

Sub-Assembly

Our flexible and dynamic work cells offer a prime opportunity for customers to drive cost reduction and enhance the value of their supply chain. With sub-assembly capabilities, we enable customers to achieve their manufacturing goals by delivering seamless execution and streamlined delivery, often at a more cost-effective rate.

How Holloway Emerge can support your next project

Whether you're seeking custom-moulded parts or high-volume production runs, rest assured that we have the expertise to deliver exceptional results promptly and consistently. Our unwavering dedication to quality, efficiency, and customer satisfaction positions us as the perfect partner for your next project. At Holloway Group, we possess the capability to process a wide range of engineering polymers for injection moulding, encompassing various materials and ensuring versatility for your specific needs.

- ABS

- ASA

- GPPS

- HIPS

- HDPE

- LDPE

- MIPS

- PA6 (unfilled and GRF)

- PC (unfilled and GRF)

- PETG

- PMMA

- POM

- PP

- PC

- PPO

- PUR

- SAN

- TPE's

Let's work together! Our specialist teams are here to help.

For a quick response, fill out as much as you can or alternatively call the team on 02 9603 2088.