Diverse range of manufacturing capabilities

Holloway Emerge offers a diverse range of manufacturing capabilities, including injection moulding, plastic extrusion, structural foam, and gas injection moulding. We also provide post-moulding processes such as ultrasonic welding, pad printing, sequential numbering, and hot stamping. With our comprehensive suite of services, we can meet your specific manufacturing requirements and deliver a wide range of high-quality finished products.

Get in Touch with Us

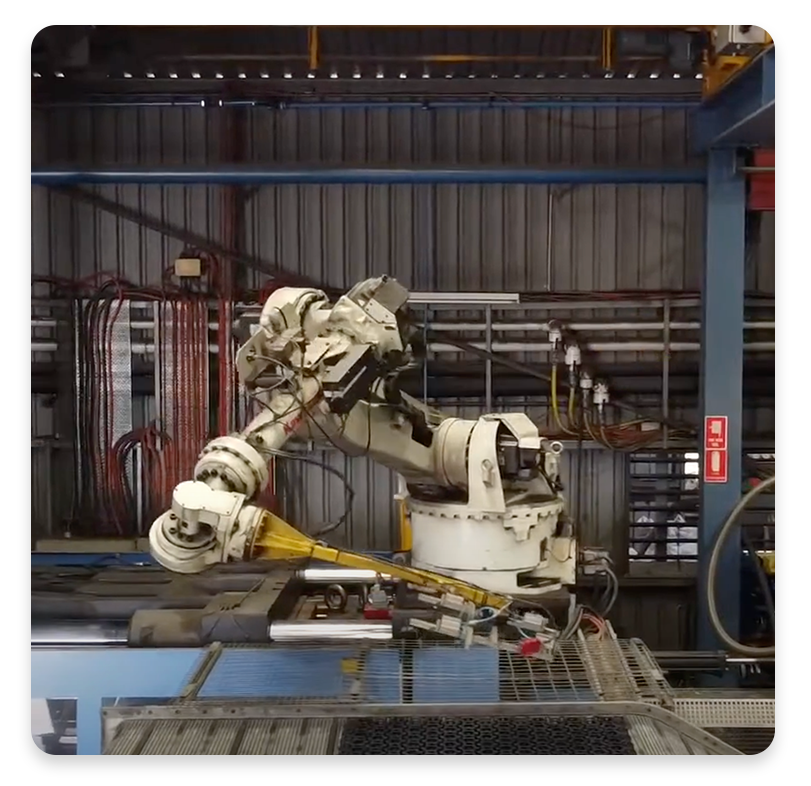

At Holloway Emerge, our manufacturing capabilities are equipped with 14 state-of-the-art, energy-efficient moulding machines. These machines are seamlessly integrated with robotics, guaranteeing consistency in both product quality and cycle time. Our extensive capacity allows us to mould products ranging from as light as 5 grams to as heavy as 13 kilograms. Additionally, our unique overhead crane systems enable us to handle and lift 20-tonne moulds efficiently.

With both Quality ISO 9001 and Environment ISO 14001 certification, we uphold stringent quality standards throughout our operations. Each of our machines is equipped with real-time monitoring and analysis software, providing valuable insights for quality control. Our experienced team of injection moulding technicians ensures the delivery of consistent quality for every moulded product we produce.

With our comprehensive suite of services, we can meet your specific manufacturing requirements and deliver a wide range of high-quality finished products.

Get In TouchLet's work together! Our specialist teams are here to help.

For a quick response, fill out as much as you can or alternatively call the team on 02 9603 2088.